The automobile started as a tool for transportation but has become so much more than that in the last 130 years.

For many, it’s a symbol of individuality, a form of expression.

It also marries artful design with engineering to create genuinely stunning and mechanically exceptional machines.

Few carmakers can combine the two different vocations into something truly extraordinary, but Bugatti does come to mind.

It’s latest, the Chiron, is an engineering marvel that looks great at 261 miles per hour (420 kilometres per hour) or zero. A new documentary dives into the Chiron’s build process, giving a peek behind the hypercar curtain.

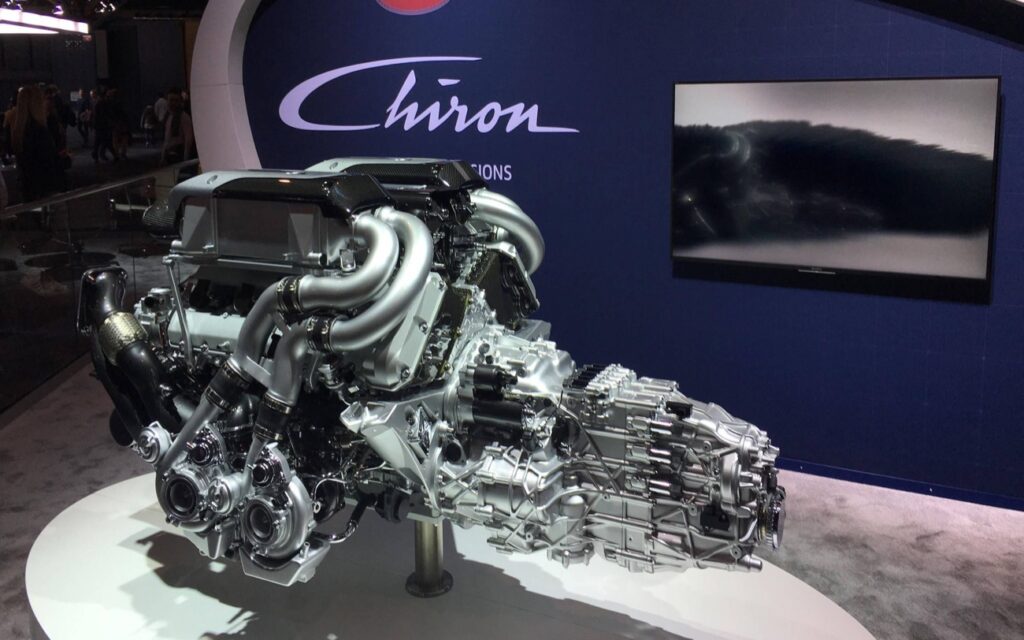

The W16 engine alone has about 3,700 parts

The documentary begins in the company’s Molsheim, France, headquarters to marry the front and rear pieces of the chassis together before heading to Germany, where the 8.0-litre W16 is built.

There are only eight technicians worldwide certified to build the beastly powerplant, and the team produces about three engines a week, which uses about 3,700 parts. Becoming a Bugatti engine builder requires an additional two years of training.

The mill is just one of the 2,600 pieces that complete the car, which takes about two months to finish.

Slowly, the car comes together, like installing the wiring harness, which is built to be both compact and light.

The Chiron features 2.5 kilometres (1.55 miles) of wiring. It’s a slow process, too, taking four days alone to attach the pristine body panels, with the last part being the active wing.

The Chiron has been around for four years and has spawned several variants and one-offs, ranging from the Divo to the Pur Sport. With 1,500 bhp (1,118 kilowatts) and a top speed of 261 mph, the Chiron is both beastly and beautiful.

It’s sleek, fast – sprints to 60 miles per take 2.3 seconds – and endlessly customisable to the customer’s taste. Its nearly £2.8 million price tag feels justified